The Fittings of Drill String

-

China high quality drop-in check valve

·Pressure Rating: Built to withstand high pressure environments, ensuring operational integrity under various conditions.

·Material Construction: Typically manufactured from high-grade, corrosion-resistant materials for enhanced durability and longevity.

·Functionality: Its primary function is to allow fluid to flow in one direction, while preventing backflow.

·Design: Compact and simple design for ease of installation and removal.

· Compatibility: It is compatible with a variety of drilling tools and wellheads.

·Maintenance: Minimal maintenance required due to its robust construction and reliable performance.

·Safety: Provides additional safety by reducing the risk of blowouts and maintaining well control.

-

China Kelly Cock valve Manufacturing

Kelly Cock Valve is designed and manufactured as a one-piece or a two-piece

Kelly Cock Valve for free passage and maximum circulation of the drilling fluid minimizing pressure loss.

We manufacture Kelly Cock bodies from chromoly steel and use the latest in stainless, monel and bronze for the internal parts, meeting NACE specifications for use in sour service.

Kelly Cock Valve is available in one or two-piece body construction and is supplied with either API or proprietary connections.

Kelly Cock valve is available in 5000 or 10,000 PSI.

-

China Lifting Sub Manufacturing

Manufactured from 4145M or 4140HT alloy steel.

All lifting subs are complied with API standard.

A lifting sub enables the safe, effective and efficient handling of straight OD tubulars such as drill collars, shock tools, directional equipment jars, and other tools using the drill pipe elevators.

Lifting subs are simply screwed to the top of the tool and feature an elevator groove.

-

integral spiral blade string drilling stabilizer

1. Size: Available in various sizes to match the hole size.

2. Type: Can be both integral and replaceable sleeve types.

3. Material: Made from high-strength alloy steel.

4. Hardfacing: Equipped with tungsten carbide or diamond inserts for wear resistance.

5. Function: Used to control hole deviation and prevent differential sticking.

6. Design: Spiral or straight blade designs are common.

7. Standards: Manufactured in accordance with API specifications.

8. Connection: Available with API pin and box connections to match other components in the drill string.

-

Oil Drilling Drill Pipes Crossover Sub

Length: Ranges from 1 to 20 feet, typically 5, 10, or 15 feet.

Diameter: Common sizes are from 3.5 to 8.25 inches.

Connection Types: Combines two different types or sizes of connection, typically one box and one pin.

Material: Usually made of heat-treated, high-strength alloy steel.

Hardbanding: Often included for extra wear and corrosion resistance.

Pressure Rating: Intend for high-pressure drilling conditions.

Standards: Manufactured to API specifications for compatibility with other drill string components.

-

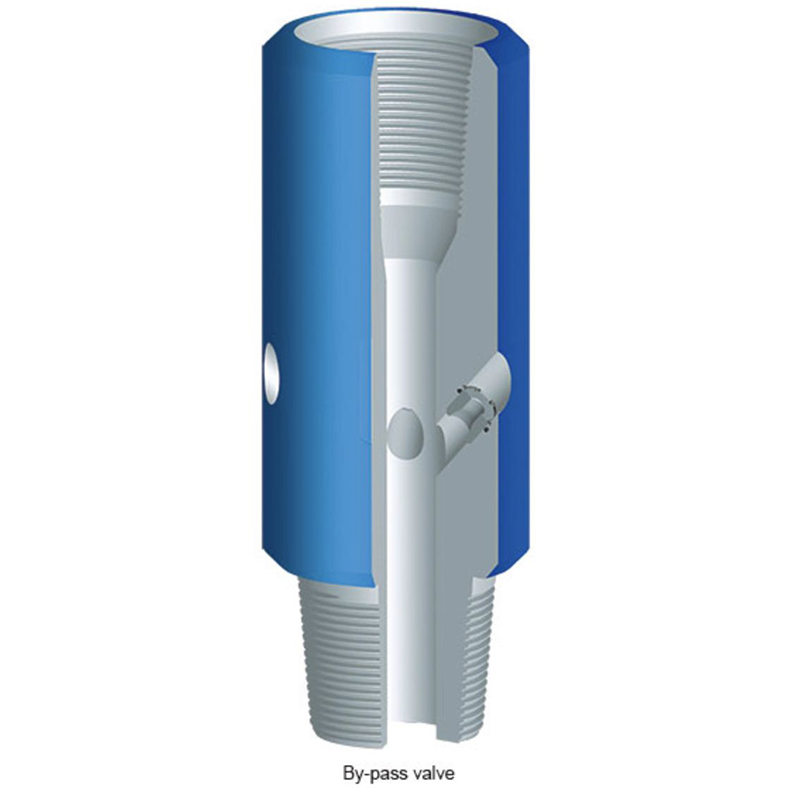

Multiple Activation Bypass Valve

Versatility: Compatible with a variety of drilling conditions, suitable for standard, directional, or horizontal drilling.

Durability: Built with high-strength, heat-treated alloy steel to withstand harsh downhole conditions.

Efficiency: Allows continuous fluid circulation and effective hole cleaning while running in or pulling out, reducing non-productive time.

Safety: Mitigates the risks associated with differential sticking, hole collapse, and other drilling hazards.

Customization: Available in various sizes and thread types to match drill pipe specifications.

-

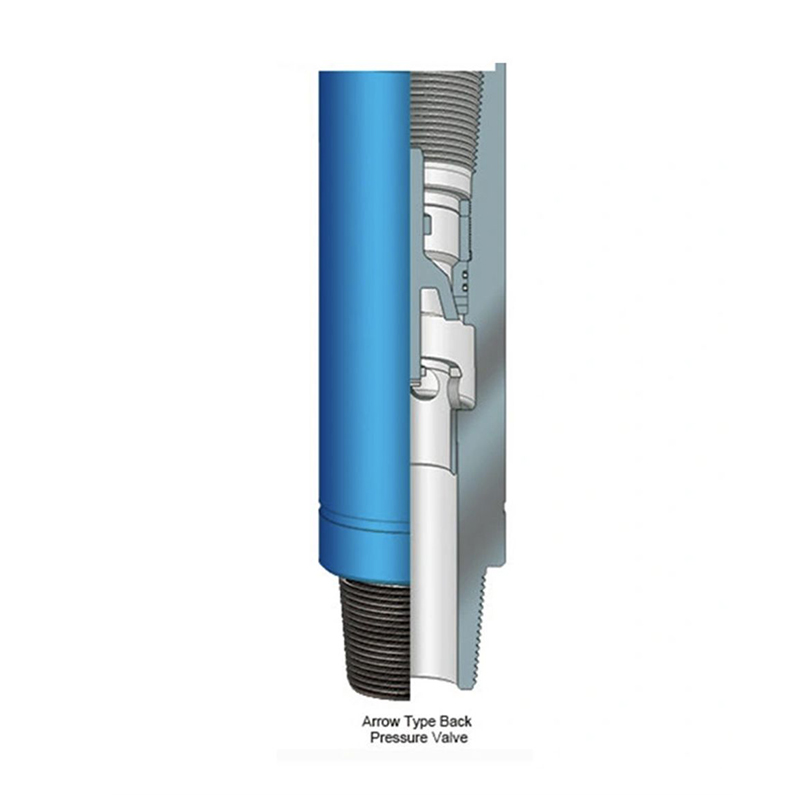

Oilfield Arrow Type Back Pressure Valve

Metal to metal sealing;

The simple design allows easy maintenance.

Pressure Rating: Available from low to high-pressure operations.

Material: High-strength, corrosion-resistant alloy, suitable for extreme environments.

Connection: Conforming to API or specific customer requirements.

Function: Prevents backflow in the tubing string, maintaining pressure control.

Installation: Easy to install with standard oilfield tools.

Size: Available in multiple sizes to fit a variety of tubing diameters.

Service: Suitable for high-temperature, high-pressure, and sour gas environments.